8D Template

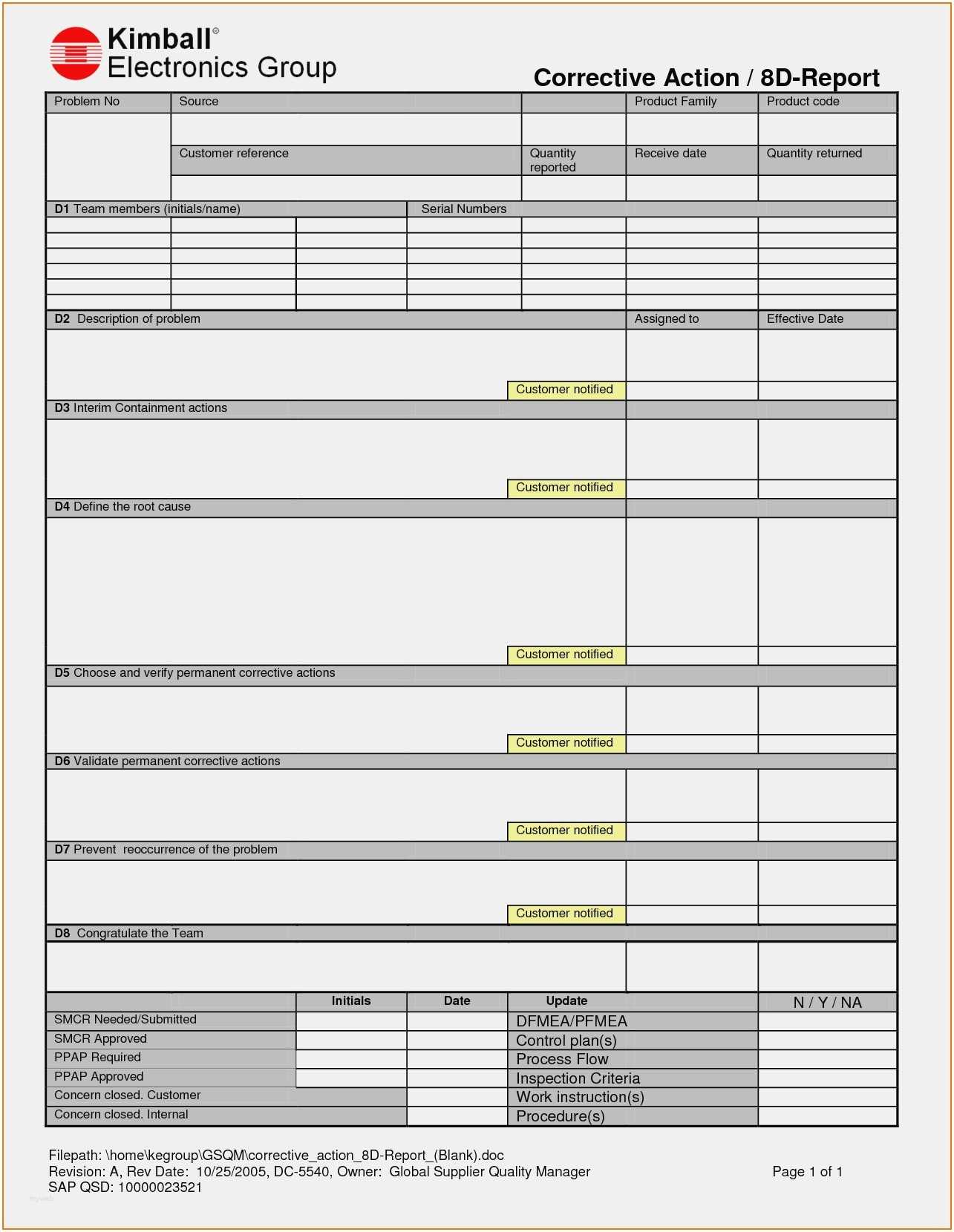

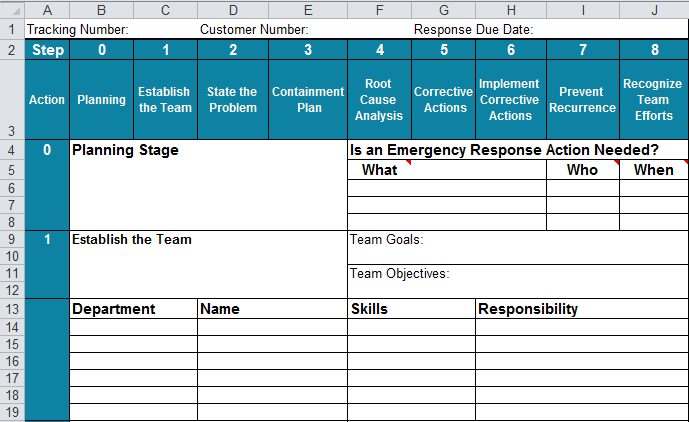

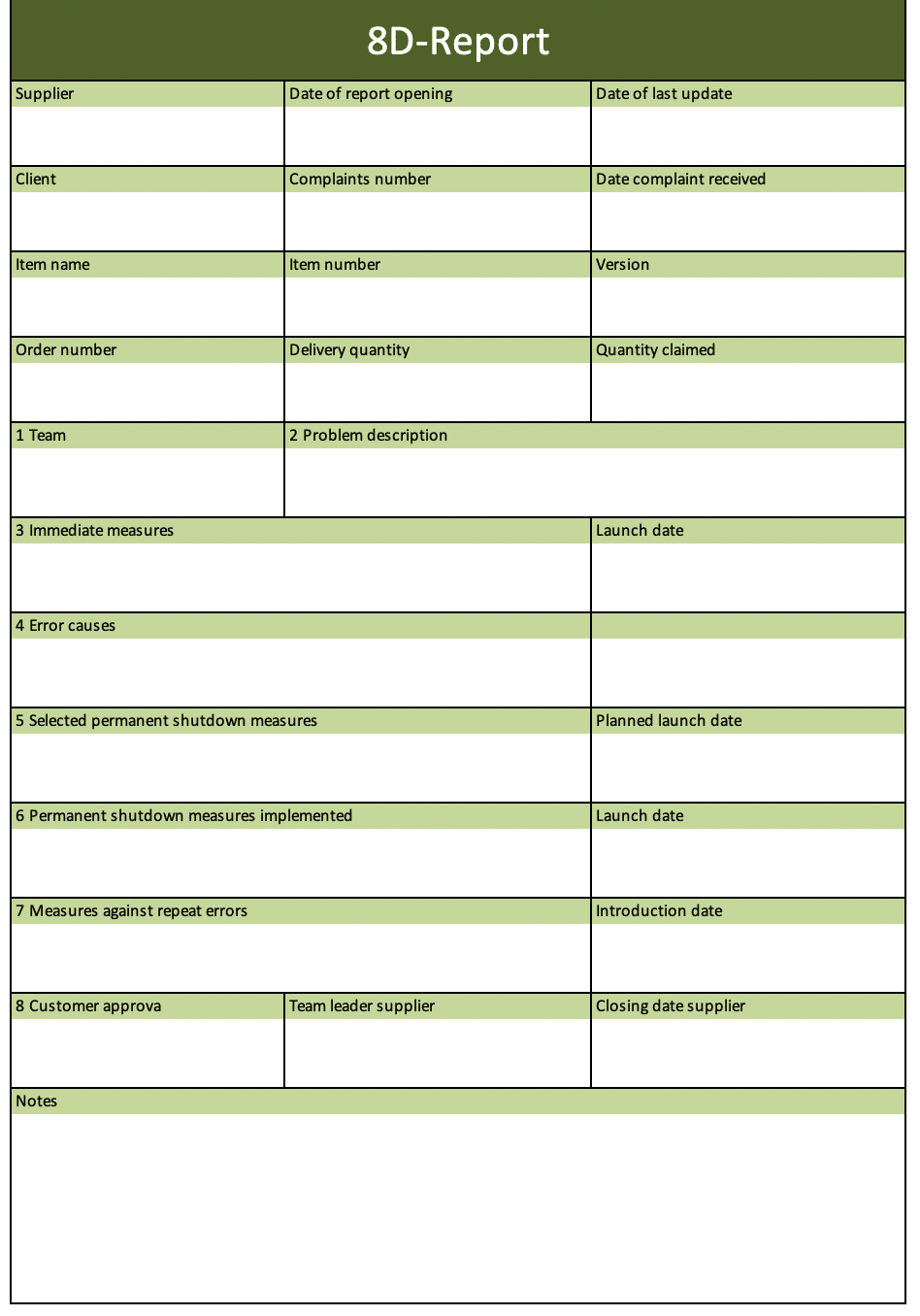

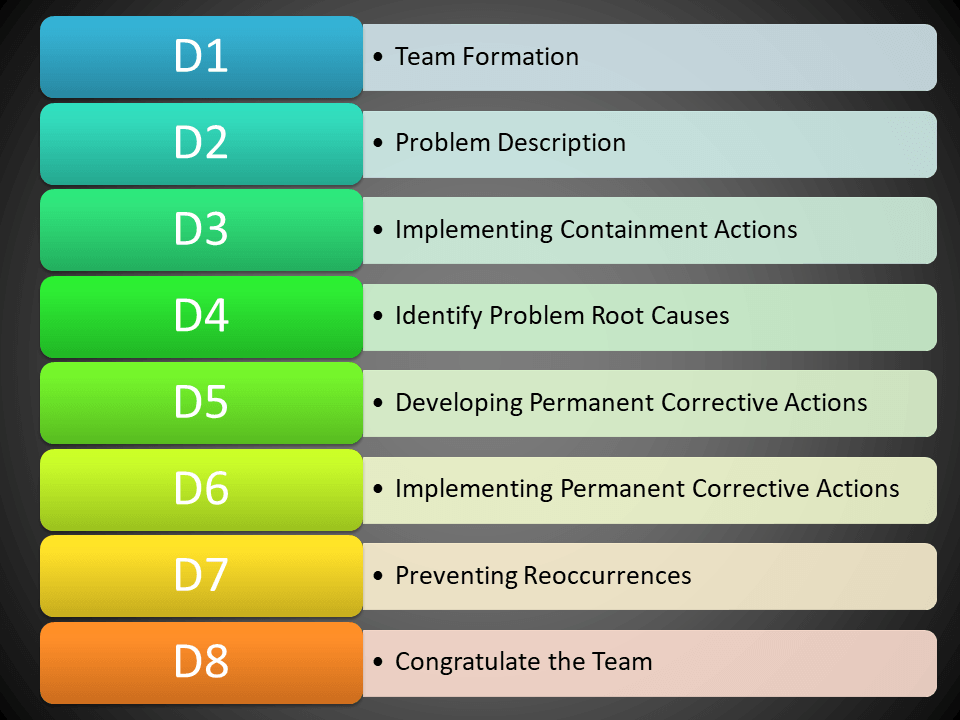

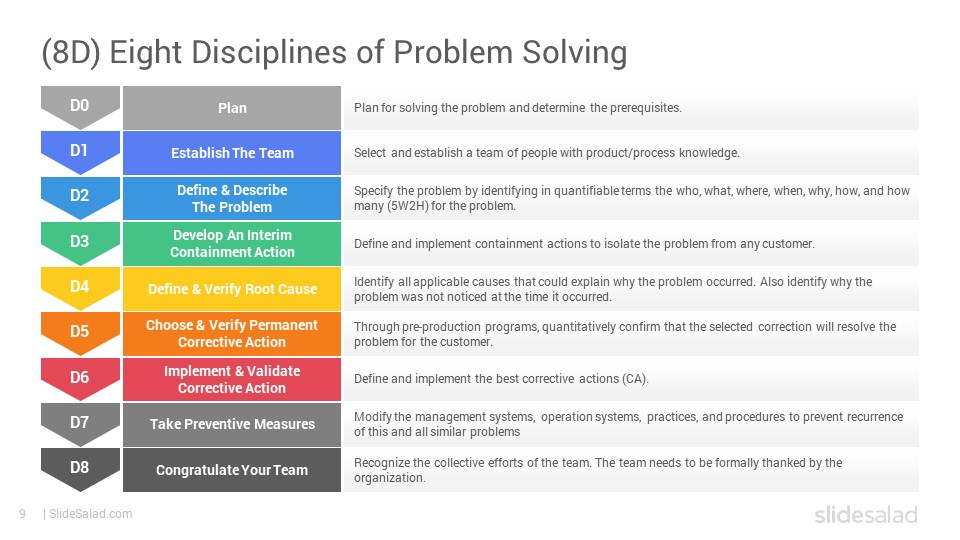

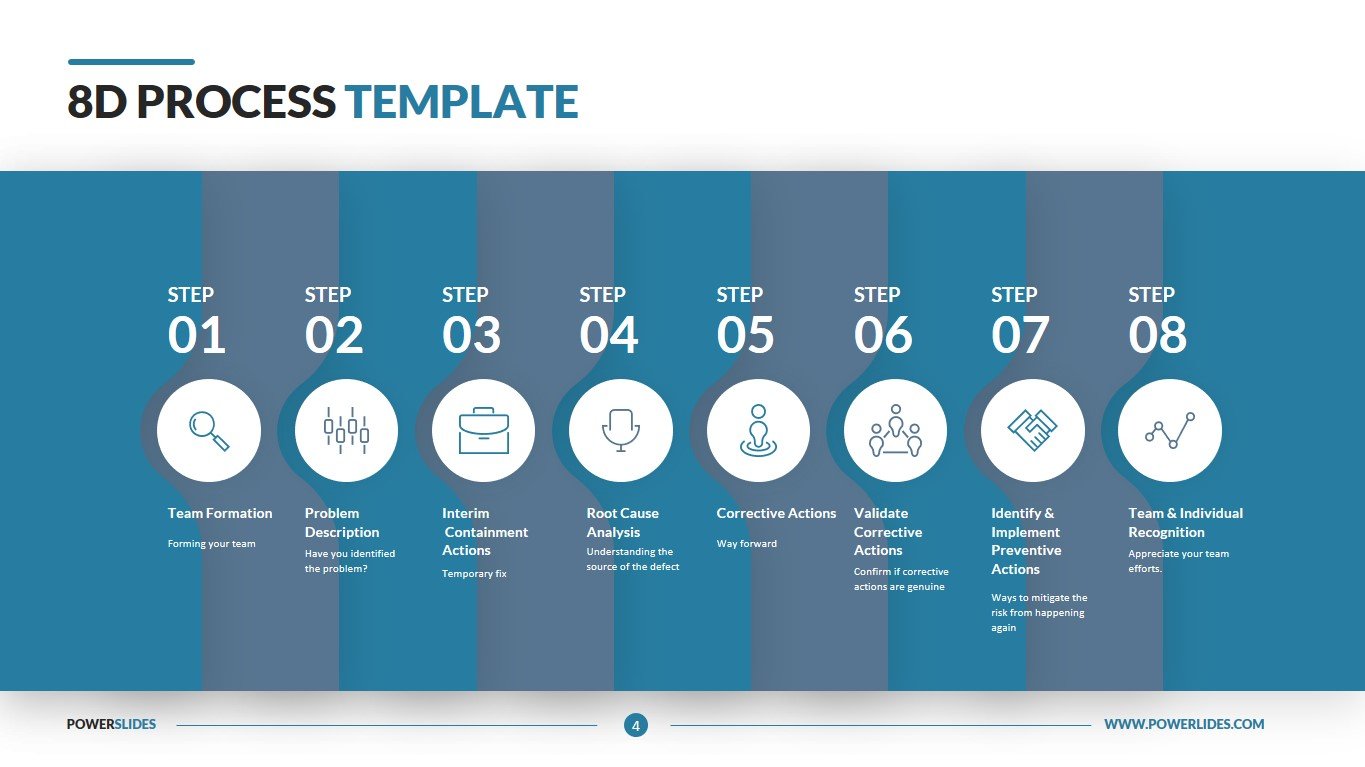

8D Template - Integrating good root cause analysis practices is one way to improve your workflow's overall efficiency. Dmaic, which is the right choice? Take a look at some of the best software packages for visualization. The 5 whys are a great way to get to the bottom of a problem without outside analysis or hypotheses in place. Why should you ask why? This guide covers some handy tips. Learn all about this method in our informative article. Don't know where to start when conducting an fmea? What are the best tools available today for creating fishbone diagrams? Problems weighing your proejct down? Find out how these approaches differ and which to reach for when improving your processes. This guide covers some handy tips. Yet despite the need to manage risks with care, six sigma teams and others involved. Take a look at some of the best software packages for visualization. Why should you ask why? Dmaic, which is the right choice? Don't know where to start when conducting an fmea? The 5 whys are a great way to get to the bottom of a problem without outside analysis or hypotheses in place. What are the best tools available today for creating fishbone diagrams? Risk management is a systematic process to handle risks in every aspect of a project. Find out how these approaches differ and which to reach for when improving your processes. Problems weighing your proejct down? Yet despite the need to manage risks with care, six sigma teams and others involved. Why should you ask why? Integrating good root cause analysis practices is one way to improve your workflow's overall efficiency. Find out how these approaches differ and which to reach for when improving your processes. Integrating good root cause analysis practices is one way to improve your workflow's overall efficiency. Take a look at some of the best software packages for visualization. Dmaic, which is the right choice? Risk management is a systematic process to handle risks in every aspect. Dmaic, which is the right choice? Yet despite the need to manage risks with care, six sigma teams and others involved. Red x is a methodology for identifying variation and defects in your production. Integrating good root cause analysis practices is one way to improve your workflow's overall efficiency. Find out how these approaches differ and which to reach for. Risk management is a systematic process to handle risks in every aspect of a project. Red x is a methodology for identifying variation and defects in your production. Problems weighing your proejct down? It is focused on product. The 8d process, also known as the eight disciplines of problem solving, is a method developed at ford motor company used to. What are the best tools available today for creating fishbone diagrams? Risk management is a systematic process to handle risks in every aspect of a project. Learn all about this method in our informative article. It is focused on product. Integrating good root cause analysis practices is one way to improve your workflow's overall efficiency. Why should you ask why? This guide covers some handy tips. The 5 whys are a great way to get to the bottom of a problem without outside analysis or hypotheses in place. Dmaic, which is the right choice? The 8d process, also known as the eight disciplines of problem solving, is a method developed at ford motor company used. Integrating good root cause analysis practices is one way to improve your workflow's overall efficiency. Dmaic, which is the right choice? Red x is a methodology for identifying variation and defects in your production. The 5 whys are a great way to get to the bottom of a problem without outside analysis or hypotheses in place. Why should you ask. Red x is a methodology for identifying variation and defects in your production. Risk management is a systematic process to handle risks in every aspect of a project. Problems weighing your proejct down? The 5 whys are a great way to get to the bottom of a problem without outside analysis or hypotheses in place. The 8d process, also known. Red x is a methodology for identifying variation and defects in your production. The 5 whys are a great way to get to the bottom of a problem without outside analysis or hypotheses in place. It is focused on product. Learn all about this method in our informative article. Don't know where to start when conducting an fmea? Problems weighing your proejct down? Yet despite the need to manage risks with care, six sigma teams and others involved. Take a look at some of the best software packages for visualization. Integrating good root cause analysis practices is one way to improve your workflow's overall efficiency. Why should you ask why? The 8d process, also known as the eight disciplines of problem solving, is a method developed at ford motor company used to resolve problems. Risk management is a systematic process to handle risks in every aspect of a project. Take a look at some of the best software packages for visualization. Integrating good root cause analysis practices is one way to improve your workflow's overall efficiency. Red x is a methodology for identifying variation and defects in your production. This guide covers some handy tips. Don't know where to start when conducting an fmea? The 5 whys are a great way to get to the bottom of a problem without outside analysis or hypotheses in place. Learn all about this method in our informative article. Dmaic, which is the right choice? Yet despite the need to manage risks with care, six sigma teams and others involved. Why should you ask why?8D Report Template

8D Problem Solving PowerPoint Template

8D Report Template

8D Problem Solving Template Printable Word Searches

8d Template Excel

8D Template Excel

Free 8d Problem Solving Template PRINTABLE TEMPLATES

8d Problem Solving Template

8D Problem Solving Template

8d Problem Solving Template

What Are The Best Tools Available Today For Creating Fishbone Diagrams?

It Is Focused On Product.

Problems Weighing Your Proejct Down?

Find Out How These Approaches Differ And Which To Reach For When Improving Your Processes.

Related Post: