Pfep Template

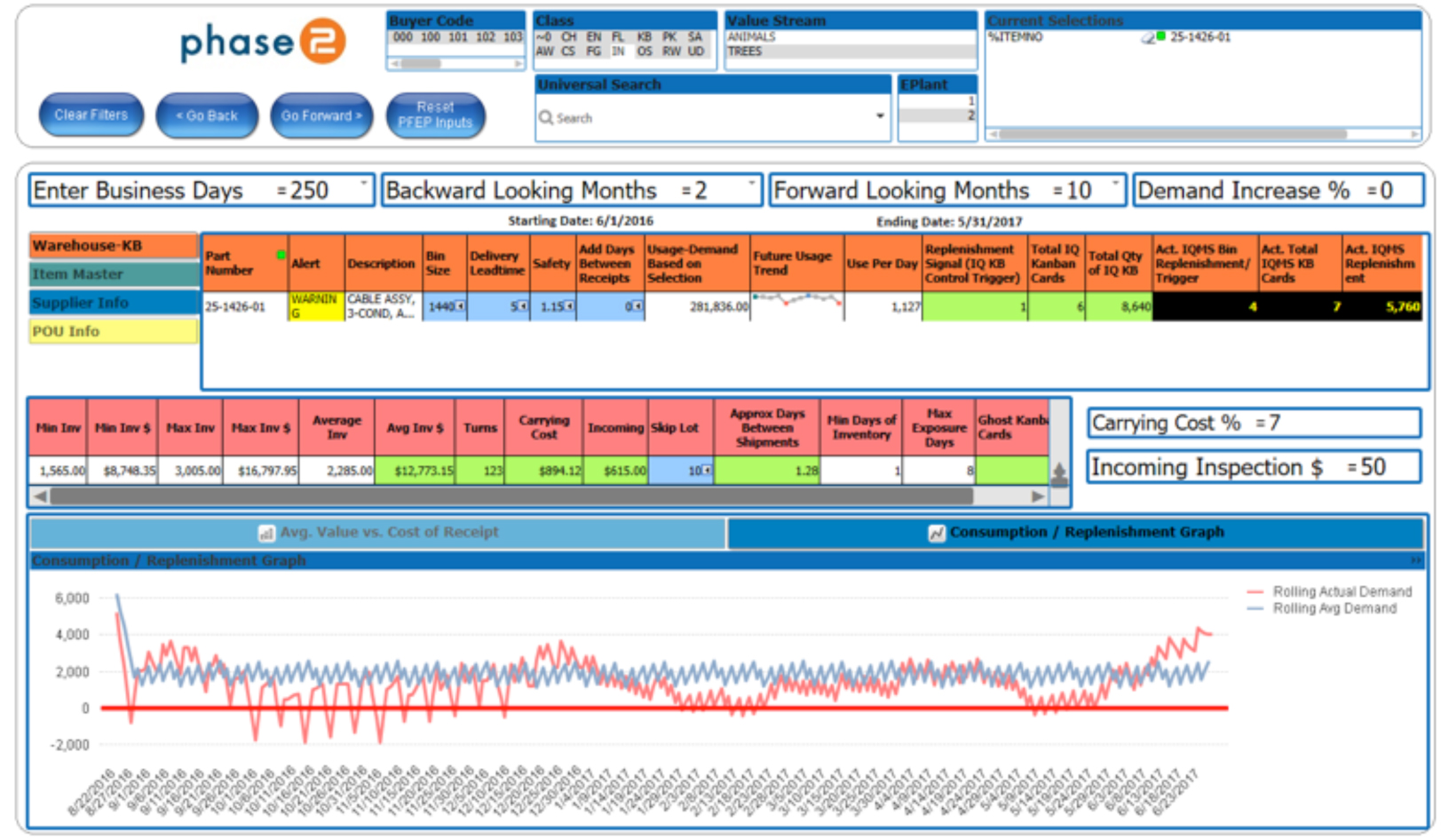

Pfep Template - Essentially an electronic spreadsheet or database, the pfep fosters precise, accurate, and controlled inventory reduction, while serving as the foundation for the. Plan for every part (pfep) is a lean manufacturing methodology that allows businesses to optimize their supply chains by reducing inventory waste and increasing. Pfep is a systematic, centralized, and accessible application used in project management and implementation of a product in development. It involves a comprehensive planning approach facilitating supply chain visibility. A pfep keeps all parts inventory information in a. What is plan for every part (pfep)? Originating from the principles of lean. Pfep, or “plan for every part,” provides solutions for optimizing inventory and supply chain processes. Pfep optimizes the policies that define how to procure each part. The pfep is used to define a plan (at part level) for the most efficient replenishment and. In this article, we will. Originating from the principles of lean. Plan for every part (pfep) is a structured methodology that plays a critical role in modern supply chain and inventory management systems. The pfep is used to define a plan (at part level) for the most efficient replenishment and. It can also be used to manage changes related to. It involves a comprehensive planning approach facilitating supply chain visibility. The “plan for every part” (pfep) methodology is a powerful tool that streamlines operations, minimizes waste, and optimizes inventory management. Essentially an electronic spreadsheet or database, the pfep fosters precise, accurate, and controlled inventory reduction, while serving as the foundation for the. Pfep optimizes the policies that define how to procure each part. Pfep is a systematic, centralized, and accessible application used in project management and implementation of a product in development. Pfep, or “plan for every part,” provides solutions for optimizing inventory and supply chain processes. What is plan for every part (pfep)? It involves a comprehensive planning approach facilitating supply chain visibility. Originating from the principles of lean. Plan for every part (pfep) is a lean manufacturing methodology that allows businesses to optimize their supply chains by reducing inventory waste. Essentially an electronic spreadsheet or database, the pfep fosters precise, accurate, and controlled inventory reduction, while serving as the foundation for the. Plan for every part (pfep) is a structured methodology that plays a critical role in modern supply chain and inventory management systems. Pfep optimizes the policies that define how to procure each part. Originating from the principles of. Plan for every part (pfep) is a structured methodology that plays a critical role in modern supply chain and inventory management systems. The pfep is a digital spreadsheet or database featuring all the critical information about parts used within a manufacturing company. Plan for every part (pfep) is a lean manufacturing methodology that allows businesses to optimize their supply chains. Originating from the principles of lean. Pfep optimizes the policies that define how to procure each part. Pfep, or “plan for every part,” provides solutions for optimizing inventory and supply chain processes. Pfep is a systematic, centralized, and accessible application used in project management and implementation of a product in development. A pfep keeps all parts inventory information in a. Plan for every part (pfep) is a lean manufacturing methodology that allows businesses to optimize their supply chains by reducing inventory waste and increasing. The “plan for every part” (pfep) methodology is a powerful tool that streamlines operations, minimizes waste, and optimizes inventory management. It involves a comprehensive planning approach facilitating supply chain visibility. The pfep is used to define. Pfep optimizes the policies that define how to procure each part. Essentially an electronic spreadsheet or database, the pfep fosters precise, accurate, and controlled inventory reduction, while serving as the foundation for the. Pfep, or “plan for every part,” provides solutions for optimizing inventory and supply chain processes. Plan for every part (pfep) is a lean manufacturing methodology that allows. Plan for every part (pfep) contains detailed information about every single part used in the manufacturing process, right from raw materials to finished goods. Plan for every part (pfep) is a lean manufacturing methodology that allows businesses to optimize their supply chains by reducing inventory waste and increasing. Pfep is a systematic, centralized, and accessible application used in project management. Plan for every part (pfep) is a structured methodology that plays a critical role in modern supply chain and inventory management systems. Plan for every part (pfep) contains detailed information about every single part used in the manufacturing process, right from raw materials to finished goods. Originating from the principles of lean. A pfep keeps all parts inventory information in. Originating from the principles of lean. It can also be used to manage changes related to. The “plan for every part” (pfep) methodology is a powerful tool that streamlines operations, minimizes waste, and optimizes inventory management. Plan for every part (pfep) is a structured methodology that plays a critical role in modern supply chain and inventory management systems. Pfep is. Plan for every part (pfep) is a structured methodology that plays a critical role in modern supply chain and inventory management systems. Essentially an electronic spreadsheet or database, the pfep fosters precise, accurate, and controlled inventory reduction, while serving as the foundation for the. The pfep is a digital spreadsheet or database featuring all the critical information about parts used. Essentially an electronic spreadsheet or database, the pfep fosters precise, accurate, and controlled inventory reduction, while serving as the foundation for the. What is plan for every part (pfep)? Pfep is a systematic, centralized, and accessible application used in project management and implementation of a product in development. A pfep keeps all parts inventory information in a. It can also be used to manage changes related to. Originating from the principles of lean. The pfep is a digital spreadsheet or database featuring all the critical information about parts used within a manufacturing company. Plan for every part (pfep) contains detailed information about every single part used in the manufacturing process, right from raw materials to finished goods. The “plan for every part” (pfep) methodology is a powerful tool that streamlines operations, minimizes waste, and optimizes inventory management. It involves a comprehensive planning approach facilitating supply chain visibility. Pfep, or “plan for every part,” provides solutions for optimizing inventory and supply chain processes. Plan for every part (pfep) is a structured methodology that plays a critical role in modern supply chain and inventory management systems.Sample PFEP database [Authors] Download Scientific Diagram

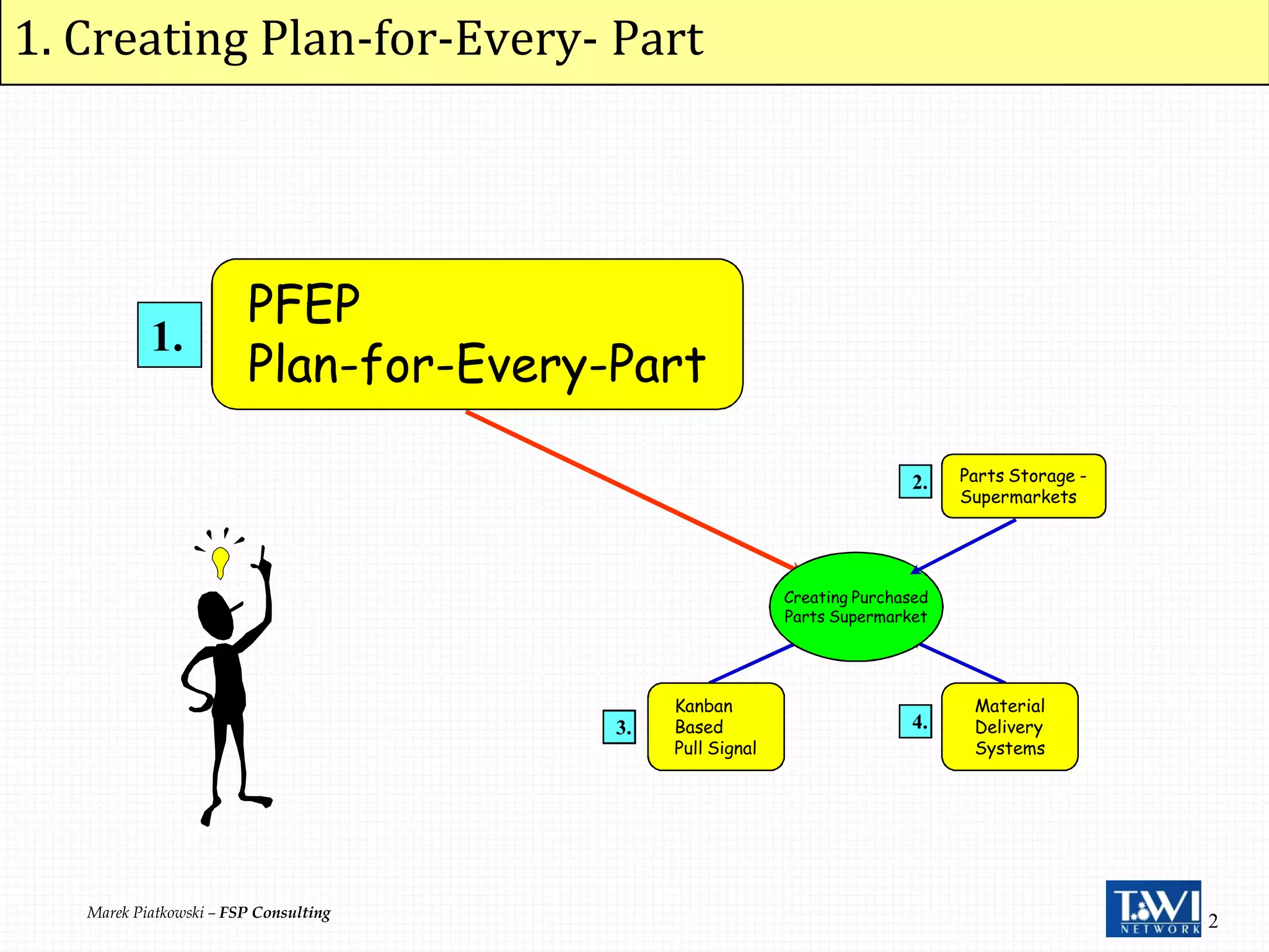

PSLPI PFEP Plan for Every Part Presentation PPT Slide Deck

Sample PFEP database [Authors] Download Scientific Diagram

PSLPI PFEP Plan for Every Part Presentation PPT Slide Deck

Pfep Format Clearance Shops www.yakimankagbu.ru

PFEP Template (English) Doc Template pdfFiller

Plan for Every Part (PFEP) in Lean Manufacturing

PSLPI PFEP Plan for Every Part Presentation PPT Slide Deck

PSLPI PFEP Plan for Every Part Presentation PPT Slide Deck

Pfep introduction PPT

Pfep Optimizes The Policies That Define How To Procure Each Part.

Plan For Every Part (Pfep) Is A Lean Manufacturing Methodology That Allows Businesses To Optimize Their Supply Chains By Reducing Inventory Waste And Increasing.

In This Article, We Will.

The Pfep Is Used To Define A Plan (At Part Level) For The Most Efficient Replenishment And.

Related Post:

![Sample PFEP database [Authors] Download Scientific Diagram](https://www.researchgate.net/profile/Vsevolod-Bastiuchenko/publication/357008023/figure/fig1/AS:1100770116141056@1639455455102/Sample-PFEP-database-Authors.png)

![Sample PFEP database [Authors] Download Scientific Diagram](https://www.researchgate.net/profile/Vsevolod-Bastiuchenko/publication/357008023/figure/fig1/AS:1100770116141056@1639455455102/Sample-PFEP-database-Authors_Q640.jpg)